Rail Diagnostics: The Secret Life of Steel Tracks..

Steel rails endure immense stress and wear. Modern rail diagnostics detect hidden defects early, preventing breakdowns and derailments. Let’s explore how technology keeps trains safe and on track! 🚆

Rail Diagnostics: The Secret Life of Steel Tracks

Introduction:

Railway tracks may seem like tough, unbreakable steel, but just like superheroes, they have their weaknesses. Over time, these steel giants wear down, crack, and even break, causing major disruptions. But fear not! Rail diagnostics are here to save the day, keeping trains running smoothly and passengers happy. Let's dive into the world of rail diagnostics and how they prevent railway chaos.

Background

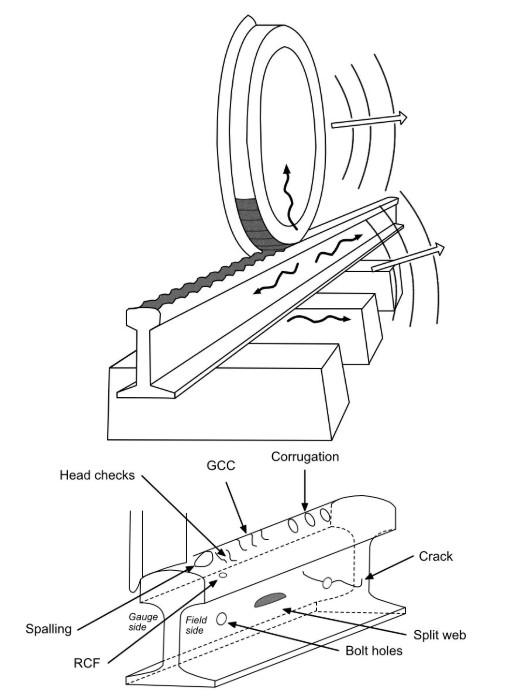

Rails, like a well-loved pair of shoes, wear out over time. But instead of just looking shabby, they can develop some rather dramatic issues—squats, wheel burns, shelling, corrugation, head-checks, and, in the worst-case scenario, full-blown rail fractures. Imagine if your car tires had an existential crisis mid-drive; that’s essentially what happens when rails fail!

So, what’s behind this slow but inevitable rail deterioration? A mix of factors, including poor rail-wheel interaction, excessive loads, wonky track geometry, damage from flat wheels, hidden manufacturing defects, and even something as seemingly minor as loose fastenings. If the rail’s hardened surface starts to degrade, wear spreads like gossip in a small town. Repeated pressure on weak spots can cause internal cracks to grow until—bam!—you’ve got a broken rail on your hands (or under your wheels, more worryingly). Damage can affect the top, sides, or even the web (the middle section of the rail, for those not fluent in railway anatomy).

Why Rail Diagnostics Matter

Every time a train rumbles along the tracks, it subjects the rails to immense forces—pushing, pulling, twisting, and flexing them like an overworked gymnast. These forces create internal stress that can lead to a range of defects, both visible and hidden. Left unchecked, these issues can escalate into rail breaks, potentially causing a train derailment. And let’s be honest, a derailed train is a far bigger headache than a delayed one.

In the past, rail inspections were like waiting for your car’s check engine light to come on—reactive rather than preventive. Engineers would assess the rails without considering load conditions, track geometry, recent maintenance work (like grinding), or traffic patterns. But times are changing, and the industry is shifting towards a smarter approach: predictive diagnostics. Sensors and advanced monitoring tools are helping engineers understand the root causes of rail damage, allowing for proactive maintenance that prevents small cracks from turning into major disasters.

Common Rail Defects (A.K.A. The Usual Suspects)

- Gauge Corner Cracking & Head Checks: Small cracks that can deepen over time and split the rail like a cracked eggshell.

- Rolling Contact Fatigue (RCF) Cracks: Hidden cracks that weaken the rail from the inside out—silent but deadly.

- Rail Corrugation: Wavy deformations on the rail surface that make for a bumpy (and noisy) ride.

- Squats & Wheel Burns: Localized damage that grows and eventually affects both the track and the wheels.

- Shelling & Spalling: Chipping away of the rail surface, leading to larger defects and potential wheel damage.

- Side & Web Cracks: These sneaky fractures can weaken the rail structure and even break fastenings like fishplates.

The Future of Rail Diagnostics: Prevention Over Cure

The key to keeping rail networks safe and efficient is early detection and proactive maintenance. With modern diagnostic tools, railway operators can track rail health in real-time, predict failure points, and schedule maintenance before things go off the rails (literally). By investing in advanced monitoring systems, the industry can cut down on costly repairs, minimize disruptions, and most importantly, ensure passenger and cargo safety.

So, the next time you hear the rhythmic clatter of a train on the tracks, remember—those rails are under constant surveillance, making sure every journey stays on the right track!

No comments yet. Login to start a new discussion Start a new discussion