Railway Track Versine: Definition, Measurement & Importance

In this article, we'll learn about the Versine on Railway Tracks, It's importance in Track Geometry and How to Measure it...

What is Versine?

The term versine refers to a measure used in railway track geometry to describe the curvature of a railway track, particularly the vertical curve. It is the distance between the midpoint of a curve and the chord of the curve, which is the straight line connecting the endpoints of the curve. The versine is used to assess the alignment and smoothness of the track, particularly in curved sections where changes in direction or alignment occur.

The versine is defined as the perpendicular distance from the midpoint of the arc of a curve to the chord connecting the two ends of the curve. This measurement is significant in determining the degree of curve (curvature) in railway tracks and helps assess the geometric precision of the track layout.

Think of versine like a rollercoaster’s track. You don’t want the track to be too flat or too sharply curved—it needs to be just right. Too much curve, and your train could feel like it’s riding a wild theme park attraction.

Why is Track Versine Important?

The versine is an important measurement in railway track geometry due to its significant role in assessing and maintaining the curvature of railway tracks, particularly in curved sections. Here are several reasons why versine is critical in railway track design, operation, and maintenance:

- Ensures Track Geometry Accuracy: The versine provides an accurate measure of the curvature of the track by determining the deviation between the circular arc of a curve and the straight line (chord) connecting its two ends. This measurement helps ensure the track follows the desired curve profile. Accurate curvature is vital for the safety of trains, especially when they are negotiating curves at high speeds. Inaccurate curves can lead to excessive forces on the wheels and track, increasing wear and risk of derailment.

- Improves Train Stability and Safety: Proper curve design, validated by versine measurements, ensures that the track does not create instability for trains. If the curvature is too sharp or uneven, it can cause track instability, which might lead to derailments. Versine helps in maintaining a smooth curve that allows trains to pass through curves without excessive lateral forces, thus reducing the likelihood of lateral instability of the rolling stock (i.e., tilting or sliding off the track).

- Enhances Passenger Comfort: Smooth curves, verified through versine measurement, are crucial for the comfort of passengers. If the curve is too sharp or misaligned, it can cause the train to sway excessively, making the ride uncomfortable or even dangerous. The lateral acceleration exerted on passengers is directly influenced by the track curvature. Correct versine measurements ensure that the curves are designed to minimize these forces, contributing to a comfortable ride.

- Guides Track Maintenance: Over time, track alignment may change due to settlement, wear, or external factors like weather and vibrations. Monitoring the versine in regular inspections allows maintenance crews to identify deviations or track misalignments that could indicate problems. Corrective actions, such as adjusting track alignment or changing the curvature of a section, can be implemented promptly to avoid further degradation or safety issues.

- Optimizes Train Speed: Curves with an appropriate versine measurement are crucial for determining the safe operating speed of a train. A gentle curve allows for higher train speeds, whereas a sharper curve may require a reduction in speed for safety. By ensuring that the versine is within designed limits, track engineers can optimize the balance between safety and speed, contributing to more efficient rail transport operations.

- Facilitates Track Design and Construction: During the design phase, versine plays a key role in calculating the radius of curves, which affects other track parameters like cant (superelevation), cross-level, and alignment. These factors together influence train handling and ride quality. The versine helps ensure that curves are smooth and uniform, reducing wear on both the track and rolling stock. This leads to lower maintenance costs over time.

- Aids in Assessing Track Deviations: When surveying existing tracks, measuring the versine helps identify areas where the track has shifted or degraded. It can indicate whether the track curve is out of tolerance, whether due to natural wear, settlements, or design flaws. By regularly measuring versine values, rail operators can prevent serious alignment issues, thus ensuring the longevity and safety of the track.

- Supports Compliance with Standards: Railways are subject to strict design and safety standards, which often prescribe limits for curvature (versine) to ensure proper train operation and safety. Proper tracking of the versine ensures compliance with these standards, avoiding potential violations and the risks associated with non-compliant track geometry.

- Helps in Curve Transitioning (Cant and Cant Deficiency): The versine can also be used in conjunction with measurements of cant (superelevation) and cant deficiency to evaluate the transition curves (the gradual change from a straight track to a curved track). This ensures smooth and safe transitions between straight and curved sections. The versine helps maintain appropriate superelevation in the curves, ensuring the centrifugal forces acting on the train are counteracted effectively for better ride quality.

- Reduction of Wear and Tear: Proper curve design and alignment, which are verified through versine measurements, help reduce the wear and tear on both the track and the rolling stock. Poorly designed or maintained curves increase the forces acting on wheels and rails, leading to faster degradation of the track structure. In the long run, well-maintained curves ensure lower maintenance costs and extend the life of both the track and the rolling stock.

How Many Types of Versine for Track Alignment?

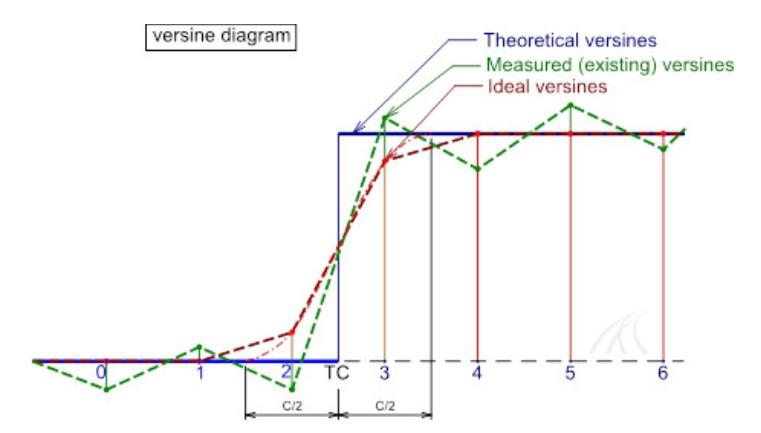

There are three types of versines used for the Railway Tracks Alignment and rectification process.

- Measured (existing) versine: The measured/existing versine refers to the versine value determined by using a real chord on the outer rail of the existing railway track. This measurement is obtained through a versine (Hallade) survey, where the curvature of the track is assessed by calculating the perpendicular distance between the midpoint of the curve and the chord. Based on this measured versine, the required track offsets (slues or slews) are computed/calculated to make the necessary adjustments and correct any deviations in the track geometry, ensuring optimal alignment and smoothness.

- Theoritical Versine:The theoretical versine refers to the versine value that is not directly measured but rather calculated using the formula:

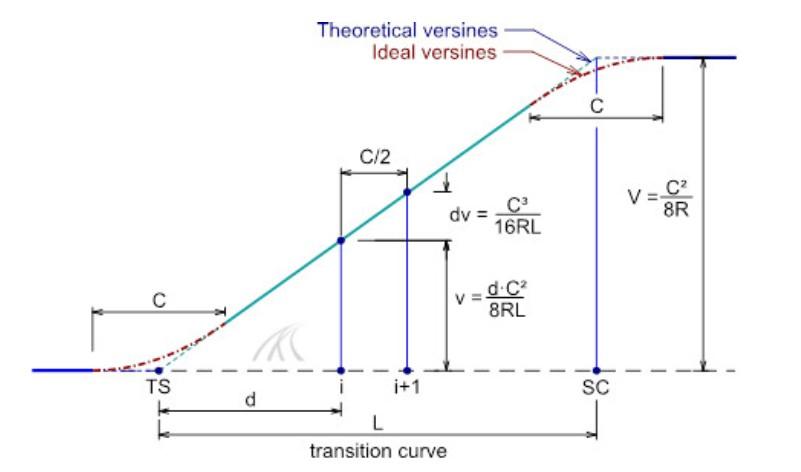

Vi = C² / 8Ri

In the calculation formula mentioned above, the:

- Vi is the versine at point i,

- C is the chord length at point i,

- Ri is the centreline radius at point i.

If the point is located on a circular curve, Ri is simply the radius of that curve. However, if the point lies on a transition curve, Ri is computed using the formula:

Ri = RL / d

where:

- RL is the radius of the main curve (the radius of the circular curve that the transition curve leads into),

- d is the distance from point i to the beginning of the transition curve,

- L is the total transition length of curve.

The theoretical versine on a transition curve is:

v = dC²/ 8RL

The versine change dv between consecutive points along the linear transition curve is:

dv = C³/ 16RL

As the name suggest, this type of versine is theoretical, computed presuming a certain chord length but without making any chord offset measurement on the ideal, nondeformed track.

The theoretical versine provides a predicted value for the curvature at any given point along the track, based on the known radius of curvature or the transition curve parameters. This calculation is used to estimate the track geometry before actual measurements are taken, providing a basis for designing and analyzing the track alignment, particularly in transition areas where the curvature gradually changes.

- Ideal Versine:The ideal versine is the vertical offset measured from a chord to the track at specific points, assuming the track is perfectly aligned and free from any irregularities.

This ideal versine corresponds to the theoretical versine when both ends of the chord lie on the same geometrical element—such as a straight line, a circular curve, or a transition curve—where the curvature remains consistent. In such cases, the ideal versine and theoretical versine are identical.

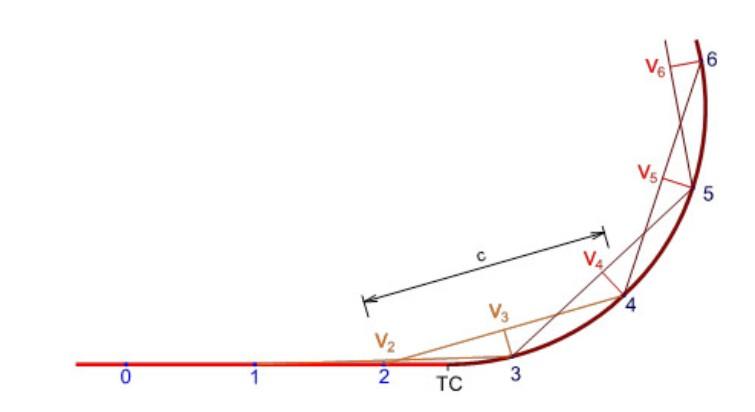

However, near areas where there is a change in curvature, such as at the junctions between different alignment elements, the ideal versine will differ from the theoretical versine. For instance, when measuring versines at points 2 and 3, the chord spans across two distinct alignment elements, which results in a discrepancy between the ideal and theoretical versines due to the curvature variation between these elements. This difference highlights the influence of track geometry changes on the versine measurement.

To measure the versine for point 2 the chord is placed between point 1 – on a straight – and point 3 – on the curve. Although not clearly visible in the figure, there is a versine V2 despite the fact that point 2 is actually on a straight, hence the theoretical versine is null.

Similarly for point 3, which requires the chord to be based on point 2 – on the straight – and on point 4 – on the curve? The versine V3, measured to the chord 2-4 is not equal to the circular arc theoretical versine.

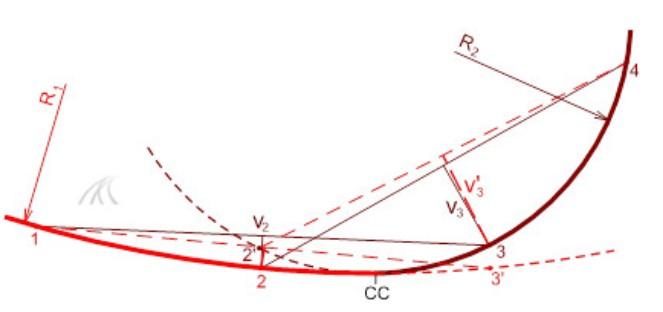

Below is another example for a compound curve.

The ideal versine v3 is measured using the chord between points 2 and 4. However, if the curve of radius R2 is extended backward to determine point 2′, the versine v3′, measured using the chord 2′−4, corresponds to the theoretical versine for a curve with radius R2.

During track realignment or rectification using methods such as Hallade, the obtained versines are compared against the ideal versines rather than the theoretical ones. When verifying track alignment on-site, the measured versine should always be assessed against the ideal versine. Additionally, if a versine on a straight section is measured using a chord placed on the adjacent curve, it is expected—even for a perfectly aligned track—to obtain a non-zero versine.

In theHallade realignment method (Ellis, 1998; Noblet, 2003), the ideal versines at the beginning or end of a transition are determined using the following principles:

- If a transition begins or ends at a half-chord point, the first or last versines are adjusted by adding or subtracting 1/6 of the total transition rise, dv.

- If the transition starts and ends precisely midway between two half-chord points, the adjustment is 1/48 of the total transition rise, dv. However, unless the transition rise is exceptionally large, this adjustment is typically considered negligible in the context of Hallade realignment.

Track Versine - Measuring Solutions

Measuring track versine is essential for assessing railway track alignment and ensuring smooth train operation. Below are traditional and modern methods used to measure track versine:

Traditional Methods (Manual & Simple Instruments)

Traditional methods for measuring track versine rely on manual techniques and simple mechanical instruments. These methods have been widely used in railway track maintenance and inspection due to their cost-effectiveness, ease of implementation, and reliability in the absence of advanced digital tools.

-

1. String Line Method (Chord Versine Measurement)

- A taut string or a fine wire is stretched between two fixed points on the rail (typically 6m, 10m, or 20m apart).

- The maximum deviation (versine) is measured using a scale at the midpoint.

- A rigid straightedge is placed across the rail at predefined chord lengths.

- The deviation from the rail profile is measured using a depth gauge.

- Track versines are recorded at half-chord points using a manual measuring setup.

- The data is plotted on graph paper to determine track alignment corrections.

Modern Methods (Digital & Automated Solutions)

Modern methods for measuring track versine leverage digital sensors, automation, and advanced data processing to ensure higher accuracy, efficiency, and real-time analysis. These technologies significantly reduce human error and allow for continuous monitoring of track geometry.

-

1. Versine Measuring Trolley (Mechanical & Digital)

- High Accuracy – Provides consistent and reliable measurements for track maintenance.

- Time-Saving – Digital models allow for faster inspections and data collection.

- User-Friendly – Designed for ease of use by track engineers and maintenance teams.

- Improved Safety – Ensures proper track alignment, reducing derailment risks.

- Small, portable sensors installed on track inspection vehicles or hand-held devices measure versine using gyroscopic and accelerometer data.

- High-speed track inspection cars equipped with laser-based or optical sensors automatically measure track versine at operational speeds.

- Uses laser scanning technology to capture precise track geometry, including versine, curvature, and elevation.

- Uses satellite-based positioning to track rail geometry deviations, including versine.

A Versine Measuring Trolley is a specialized railway track inspection device designed to measure the versine (lateral deviation) of the track over a predefined chord length. It plays a crucial role in assessing track alignment, ensuring smooth curvature transitions, and detecting any irregularities that may affect train operations. The Key advantages of using such trolley is:

🚆 Check Out Our Available Versine Measuring Trolley:

Some Fun Facts abour Railway Track Versine

Here are some less known funfacts about Railway Track Versine

- The term "versine" has its roots in ancient trigonometry, originally used by astronomers. Today, it plays a crucial role in railway track geometry, ensuring smooth and safe train movement on curves.

- Versine helps engineers maintain proper track curvature by measuring the deviation from a straight line. A well-calculated versine ensures trains can navigate curves safely at high speeds without excessive wear on wheels and rails.

- Before modern technology, railway workers used a simple string and ruler to measure versine manually. Today, advanced laser-based measuring tools and GPS-enabled track recording vehicles have revolutionized the process, making it faster and more accurate.

- For bullet trains and high-speed rail, versine calculations must be extremely precise. Even a minor miscalculation can lead to speed restrictions, passenger discomfort, and increased maintenance costs due to uneven wear on the tracks.

- The concept of versine isn’t limited to trains! It is also used in roller coaster design to ensure smooth transitions between curves, enhancing both safety and thrill factors for riders.

So, the next time you're on a train and it takes a smooth curve, just remember: that’s the magic of proper track alignment and versine at work. You can even imagine engineers behind the scenes high-fiving each other for a job well done!

No comments yet. Login to start a new discussion Start a new discussion